Humanitas University launches 3D Innovation Lab, bridging Education, Research and Industry

The 3D Innovation Lab is located in the Roberto Rocca Innovation Building on Humanitas University’s Campus. Through the development of innovative solutions based on 3D printing techniques, it aims to promote the exchange between clinical activity, scientific research and university education, and to foster strategic collaborations with biotech companies and the industrial world. Its mission is to transform laboratory discoveries into real solutions which can be applied in patient care. The team, led by Eng. Paolo Oliva, Head of Research Technology at Humanitas, is composed of biomedical and materials engineers, biomedical researchers and tissue engineering experts.

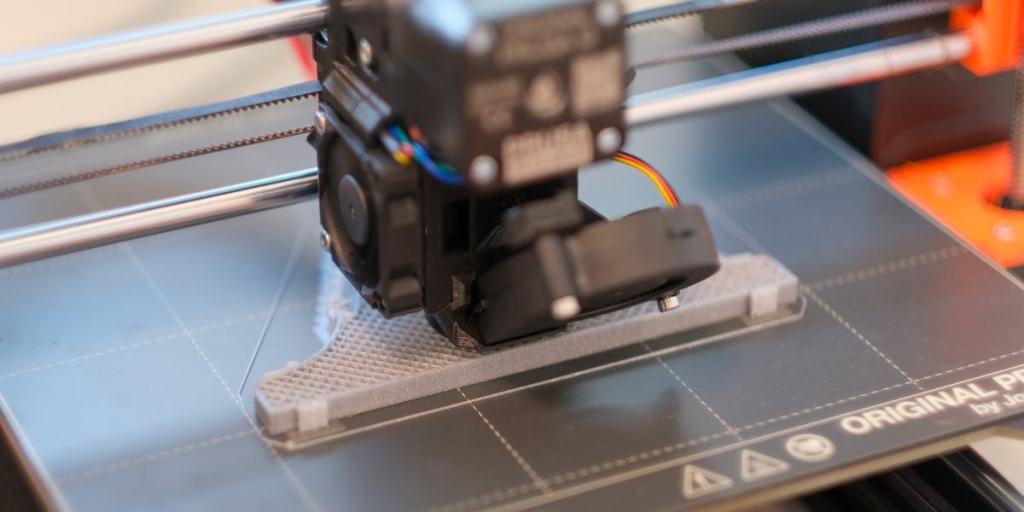

Additive manufacturing, also known as 3D printing, is revolutionising medicine and life sciences thanks to its ability to combine tissue engineering research with regenerative medicine, as well as to create realistic models for pre-clinical training and to replicate tissue structures not only at the macroscopic but also at the microscopic level.

The technologies available in the laboratory are many, including:

- A 3D scanner capable of capturing high-definition images of three-dimensional objects – such as parts of the human body – that are realistic both at the macroscopic geometric level and at the level of microscopic surface textures.

- A fleet of 3D printers capable of creating life-size organs, also thanks to the combined use of different types of resins to obtain materials with different aesthetic and mechanical properties – elasticity, resistance and porosity – in a single anatomical model. The aim is to improve training or even test devices and drug delivery strategies.

- A 3D cell bioprinter, Electrospider, was born from the collaboration between Bio3DModel – a subsidiary of SolidWorld Group – and the University of Pisa. This printer can create three-dimensional cell cultures that better replicate the body’s tissues, including tumours, where the three-dimensionality of the tumour microenvironment plays a fundamental role in pathological mechanisms.

- A bioindenter capable of analysing the biomechanical properties of tissues, which is essential to then replicate the tissue in a faithful manner through 3D printing techniques. The machine is part of the laboratory directed by Prof. Alessandro Zerbi, Head of Pancreatic Surgery at IRCCS Istituto Clinico Humanitas. The laboratory was set up three years ago in partnership with the Politecnico di Milano as well as with the support of Fondazione Humanitas per la Ricerca and aims to study and reproduce the biomechanical properties of pancreatic tissue, which is particularly challenging from a surgical point of view. This technology is a forerunner for the study of phantom organs and it is located in the spaces adjacent to the 3D Innovation Lab to foster further collaborations.

Clinical needs

The 3D printing lab aims to create patient-specific anatomical models to support the preparation and surgical execution of selected cases. These models are meticulously crafted to reflect the patient’s unique anatomical features, providing surgeons with valuable information that enhances their ability to plan and execute surgeries with unprecedented precision.

The lab is also in the process of being certified to create customised cutting guides to support the work of surgeons in the OR during complex surgeries. These customised guides are designed to improve precision, reduce operating time and improve clinical outcomes. Many collaborations are already underway: among the most involved units are liver surgery, vascular and cardiac surgery, and breast surgery.

Advanced phantoms for training

The latest 3D printing technology allows the laboratory to create high-fidelity models that reproduce healthy and pathological tissues in great detail. These models are essential for training healthcare professionals in a variety of procedures, from basic diagnostic techniques to complex surgeries. The texture and anatomical and morphological accuracy of the models allow trainees to gain practical experience in realistic scenarios, thereby increasing their competence and confidence.

By bridging the gap between theoretical knowledge and practical applications, 3D printed models play a crucial role in improving patient care and its outcomes. The 3D Innovation Lab team is already working on this front, also thanks to the close collaboration with the Mario Luzzatto Simulation Centre at Humanitas University – over 2000 square metres entirely dedicated to real-life medical simulation.

Tissue engineering and biofabrication

The 3D Innovation Lab is equipped with a ‘wet’ laboratory area where tools and technologies – such as the Electrospider cell printer – are located to create three-dimensional cell cultures of precise composition and architecture, as well as for the fabrication of biological scaffolds (support structures) capable of imitating the physical and mechanical properties of tissues. This area is open to all Humanitas researchers who want to expand their in vitro models into three dimensions, a fundamental step for the study of certain pathological processes. Some of the groups that are starting to collaborate in this area are the Neurodevelopment laboratory of Simona Lodato and the Precision Medicine laboratory of Salvatore Piscuoglio.